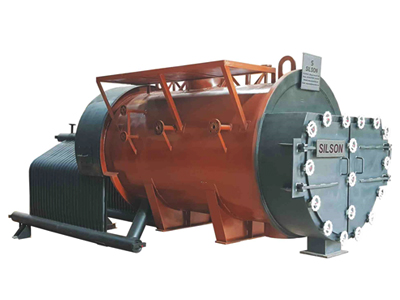

We are Manufacturer, Supplier, Exporter of Industrial Membrane Boilers, Steam Boilers, Package Boilers, Industrial Boiler Accessories, Industrial Boiler Spares from Pune, Maharashtra, India.

A Membrane Boiler is a 3-pass designed boiler. It consists of a Fluidised Bed for combustion, a Water wall, a Furnace, and a Bed Coil Assembly, all of which comes on the outside of the boiler. This type of boiler comes in 2 pieces - Boiler and Membrane Panel.

In this boiler, the fuel is added to the furnace which is present in the Membrane Panel. The panel consists of a Bed Coil Assembly. The water flows through the tubes of the panel and gets heated by the fire in the furnace. The hot water then travels to the Boiler shell, and the steam generated from the hot water then flows to the outlet of the boiler shell.

Due to the capacity and pressure that it withstands, the Membrane Boiler is classified as a High Pressure Water Tube Boiler.

Product Specifications :

- Combiflame: FBC & semi FBC Boilers

- Designed for: All types of multi-fuel

- Capacity: 2000-15000kg/hr.

- Pressure: 10.54, 15, 17.5, 21 & 28 kg/cm2.

Special Features :

- Consists of Fluidised Bed combustion that ensures High Efficiency of up to 84%.

- Comes with an Auto Fuel Feeding System and option of Ash Handling System.

- Easily accessible for maintenance and tube cleaning.

- Consists of 4-Pass design with Air Pre-heater.

- Shell with water wall & Bed Coil Assembly offers faster generation and consistent quality of flow & steam pressure.

- VFD Control Feeding System for proper regulation of fuel, depending upon the Load.

- Consists of Pumps with High Efficiency.

- Since it consists of a membrane wall construction, there is Zero Leakage of Flue Gasses.

- Optimum Steam Space is provided with a unique steam separator to generate dry steam.

- Safety aspects are maintained with strict Quality Control.

- High temperature Air Nozzles ensure longer life of the component.