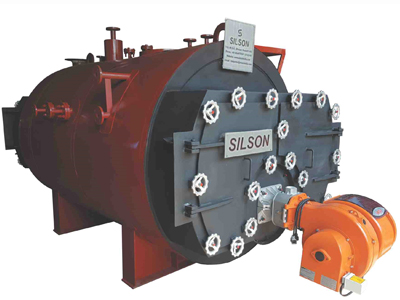

We are Manufacturer, Supplier, Exporter of Oil Fired Boilers, Gas Fired Boilers, Steam Boilers, Package Boilers, Industrial Boilers Accessories, Industrial Boiler Spares from Pune, Maharashtra, India.

Oil / Gas Fired Boilers are 3-pass internal furnace smoke-tube-type boilers in which flue gases are inside the tubes while water is outside the tubes in the shell.

The combustion of oil and gas in the furnace requires atomization of the fuel. Since the fuel entering the burner is in bulk amount, is either in liquid or gas form. Therefore it needs to be separated in fine droplets so that every last particle of the fuel could get burnt without leaving any traces. This process of separating the fluid particles is called atomization.

Generally, atomization is done with the help of high-pressure fan which also provides air for the combustion of fuel. The burners come with the attached fan and their assembly is known as a Monobloc Burner, which means that the fan is mounted on the burner.

The 3-pass oil/gas fired boilers are most suitable for the burn fuels like heavy or light oil or gas.

Difference between Oil Fired Boiler and Gas Fired Boilers :

Oil Fired Boilers generally require Day Oil Tank to store oil and this oil is transported to a burner through oil piping and oil pump.

On the other hand, High-Efficiency Gas Fired Boilers although they share the same design as the Oil Fired Boilers, the only difference is the transportation of gas to burner. Gas Fired Burners require gas a train which comprises of a regulator (to regulate pressure), and a strainer (to remove dirt from the gas). No such valves are required in oil fired boilers.

Product Specifications :

- Capacity - 500 to 6000 Kg/hr.

- Pressure - 7.0 to 17.5 Kg / cm²(g).

- Burners - Compatible with Indian as wells as imported burners

- Efficiency - Overall efficiency of 88 % (+/-2%).

Special Features :

- 3-Pass Dry Back, Semi Wet, Wet Back Boilers

- Designed for Natural Gas / LPG / CNG / PNG / Biogas / LNG & Oil – LDO / HSD / FO / LSHS / Diesel.

- Low emission (Optional) reduces Nitrogen Oxide Emission.

- CO is also lower due to increased turbulence in the combustion furnace.

- Large convective heating surface in the 2nd & 3rd pass tubes ensures excellent heat transfer.

- Advanced burner provides maximum Combustion Efficiency and turn down ratio 1.4 Efficiency at 88% (+/-2%).

- Burner provided with option of ON/OFF & step-less modulation.

- Consists of Pumps with High Efficiency.

- Large water holding & steam holding space provides quick response to fluctuating steam demands

- Large heat transfer surface reduces the thermal stresses on the boiler surfaces

- Monobloc type burner ensure reduced fuel consumption

- End-to-End visibility of tubes.

- Optimum Steam Space is provided with a unique steam separator to generate dry steam.

- Fully automatic and high efficiency saves running costs to the Steam Boilers.

- Safety aspects are maintained with strict Quality Control.